Work processes

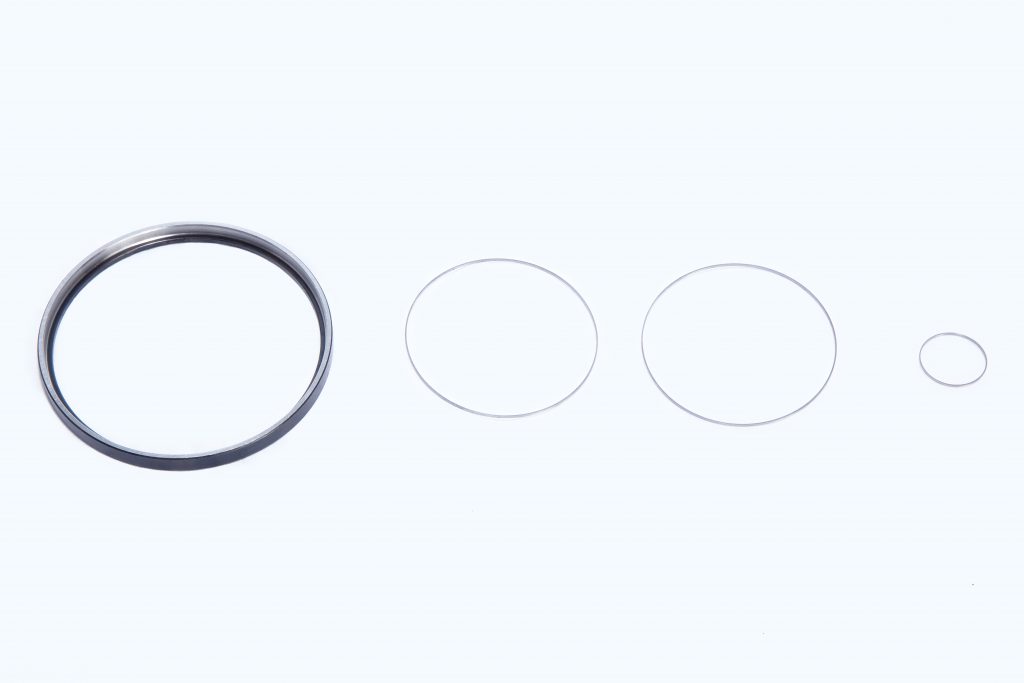

Our grinding processes involve machining individual precision mechanical components and assemblies. We grind outside diameters (Ø min. 2 mm, Ø max 250 mm) and threads, inside diameters (Ø min. 2, Ø max 300), and perform centred grinding of external shapes (e.g. polygons, eccentric components, cams, etc.). We perform centreless grinding from 2 to 40mm, multi-diameter machining and profiles to high quality standards (dimensional tolerance of 0.002 mm). Inside diameter lapping Finishing treatments such as brushing, polishing and tumbling of ground parts, deburring with Gratomat, ultrasonic cleaning, grinding of shaft centres. The main materials processed are steel, stainless steel, cast iron, ceramic and bronze.

Finished product suppliers for the hydraulics sector

Finished product suppliers for the hydraulics sector

We represent a unique reference point for the hydraulics sector: we buy turned parts from qualified suppliers, grind them with micron tolerances, perform finishing treatments, assemble units and deliver orders. The supply chain is digitally traceable, and the customer is relieved of management and administrative tasks. We ensure high quality standards thanks to cutting-edge 4.0 technologies and anthropomorphic robots, already in use together with our fleet of machines. Advanced measurement systems carry out checks to micron tolerances.

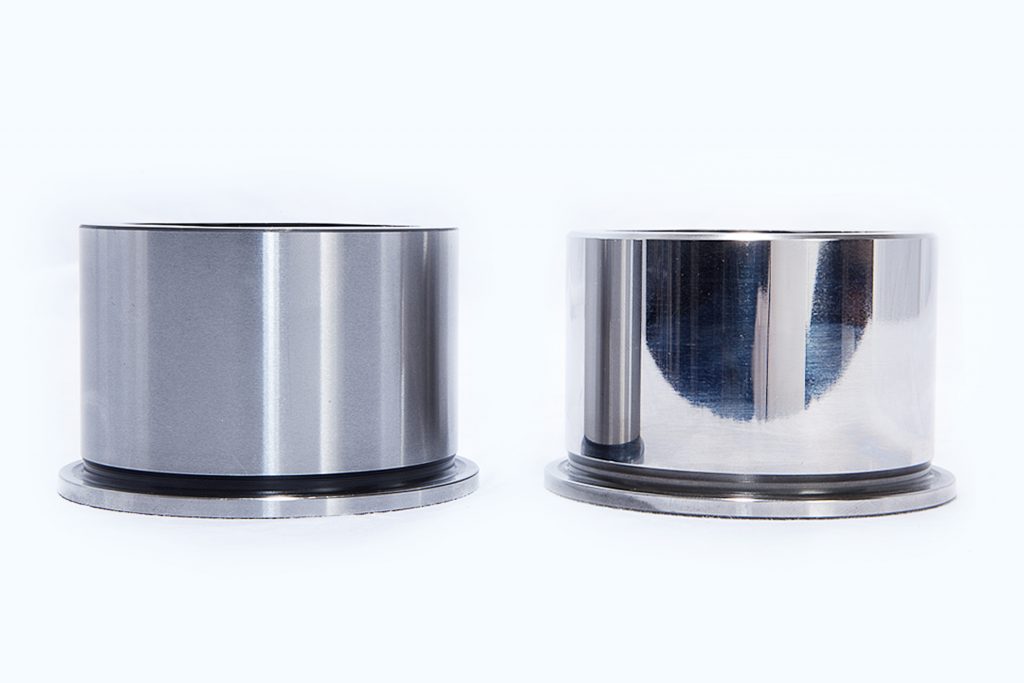

Inside diameter grinding

Ø min. 2, Ø max 300

Inside diameter grinding from 2 to 300 mm. We carry out simultaneous multiple machining of interior surfaces, radii, bevels, fillets and outside diameters. Highest quality levels, micron tolerances, machining of valve seats for the hydraulics sector, with sharp edges and radii to ensure parts seal perfectly.

Outside diameter grinding

Ø da 2 a max 250

Centreless diameter grinding

2 to 40 mm, 0.002 mm dimensional tolerance

Finishing treatments

How to improve roughness and remove micro burrs from machining

SERVICES

In addition to grinding, we offer the following services:

Co-design of mechanical and grinding solutions, on specific request

Measurement of materials and products, complete with quality documentation

Complete supplies of precision mechanical components